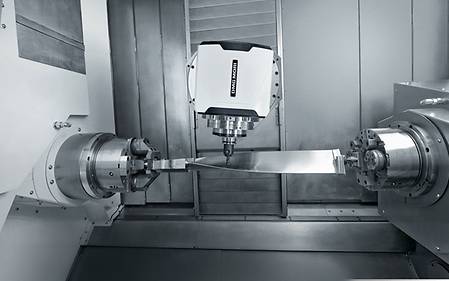

CTX beta 1250 TC

Turn & Mill complete machining with the new ultra-compact patented turn-mill spindle compactMASTER

Highlights

Complex turning and milling operations with ultra-compact turning/milling spindle and up to 20,000 rpm

- Turning and milling spindle compactMASTER with 12,000 rpm, 22 kW and 120 Nm

- ± 120 mm Y-stroke for external machining

- Swivel range of B-axis ± 110° for maximum flexibility

Tool magazine as a disk or chain magazine for shorter set-up and idle times

- Disk magazine for 24 tools in standard

- Chain magazine with 48 or 80 stations as option

- Tools up to 400 mm length and Ø 120 mm

6-sided complete machining by main spindle up to 700 Nm and optional counter spindle

- Integrated spindle drives with up to 700 Nm for maximum cutting performance

- Counter spindles up to 360 Nm and 65 mm bar capacity as option

- Optional with complete package for bar machining with automatic workpiece pickup device

Accuracy

- Precision in μm range

- Positioning accuracy up to <6 μm and repeatability up to <2 μm

- Linear scales in the linear axes of the traveling column (X1 / Y1 / Z1)

- Liquid-cooled spindles and cooling of the X- / Y- / Z-motors

Application Examples

Automation

Open up the possibilities of automation

Increase productivity and quality, and operate 24/7. Our solutions offer extended machine uptime and support sustainability. Optimize your processes with our innovative automation solutions!

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport, pallet size 800x600 mm to 1,100x1,100 mm, or 1,200 x 800 mm

- Maximum transport weight of up to 1,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Turning, robot payload 12, 25 or 35 kg

- Rapid changeover from chuck to shaft parts

- Robo2Go Vision, robot payload 35 kg

- Robust 3D camera recognition, ideal for multi-job function

- Integrated in the machine control operation via CELOS APP: No need to change your NC programs!

- Intuitive usability thanks to dialog-guided software

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- Setting up a new workpiece < 5 minutes

- Rapid changeover from chuck to shaft part storage

- Handling of shafts ø 20 – 170 mm and chuck parts ø 20 – 175 mm

- Three versions for all requirements: Robot payload 12 / 25 / 35 kg

- Stacking magazine

The storage expantion for your Robo2Go Turning

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

- Job management of all jobs via the Robo2Go Jobs app

- Robust 3D camera recognition, ideal for multijob function

- Infeed and outfeed of raw and finished parts by pallet

- Cylindrical chuck parts of ø 25 – 175 mm

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

Highly flexible and collaborative automation for workpieces up to 5 kg

- Freely movable workpiece handling, incl. robot and storage area on a trolley

- Workpieces up to 5 kg, or 2 × 2 kg with double gripper

- No infrastructure changes

- No safety fence necessary

- 600 × 900 mm footprint

- Collaborative robots, setup time <5 minutes

- Direct teaching without robot knowledge

- Easy connection via Ethernet

- Expansion (option)

- Storage for up to 108 workpieces (2-position storage for max. 36 workpieces as standard)

- Blow-off device

- Measuring system and quality check

Highly flexible and collaborative automation for workpieces up to 10 kg

- Freely movable workpiece handling, incl. robot and storage area on a trolley

- Workpieces up to 10 kg, or 5×2 kg with double gripper

- No infrastructure changes

- No safety fence necessary

- 600 × 900 mm footprint

- Collaborative robots, setup time <5 minutes*

- Direct teaching without robot knowledge

- Easy connection via Ethernet

- Two types of workpiece stockers can be selected

- Storage for up to 64 workpieces

- Blow-off device

- Regrip station

*When the optional tag position correction function is selected or when the machine / workpiece setup is already completed.

Flexible modular robot system for ≥ 1 machine

- Modular concept with standardized peripheral devices, e. g. washing, measuring or marking

- 80 % shorter setup time due to modular and standardized peripherals and robot programs

- Flexible adaptation to system changes including after installation

- Simple and easy operation via the MATRIS control system without programming

- Handling of workpieces up to ø 200 × 200 mm, 1 × 20 kg or 2 × 10 kg

- Stacking magazine:

- 14, 20 and 26 pallets: ø 150 × 120 mm, max. 35 kg per pallet

- 10 and 20 pallets: ø 200 × 200 mm, max. 75 kg per pallet

- Loading of oversized tooling in case of vertical machining center

- Available for 13 series, e. g. NLX, NTX, NHX, DMU, NMV, eVo, etc.

- Ideal for the flexible production of 50 to 200 workpieces / day

- Space-saving pallet handling for up to 40 pallets

- 400 × 400 mm pallet size

- 150 kg transfer weight (workpiece and pallet)

- Integration of secondary processes such as deburring or marking possible

- Available for the CMX 50 U, CMX 70 U, DMU 50, DMU 65 monoBLOCK, CMX 600 V, CMX 800 V, CMX 1100 V

Control & Software

Experience the speed of digital transformation (DX)

Revolutionise your operations, unlock new opportunities, increase efficiency and promote sustainability by reducing power consumption – while gaining a strong competitive advantage.

- Shorter non-productive times thanks to sorting of tools in the tool magazine according to the sequence of the tools in the program

- Time-optimized sorting in the chain magazine due to the use Of the tool shuttle instead of the spindle

* Optimization is not done in parallel to main time

- Minimized tool changing times from lot sizes > 3

- Flexible tooling in the magazine depending on the NC program

- Producing high precision oval and und polygon geometries with grinding – tolerance class IT5*

- Easy parametrized definition of the geometries based on DIN 32711

- Perfect complement to technology cycle Polygon- / Oval-Turning

* as extension of the grinding technology cycle

- New machining opportunities for more innovations on the part – e.g. shaft-hub connections.

- Position-oriented polygon and oval geometries due to 6-sided complete machining advantages

- Residual unbalance-based calculation of the permissible tool speed limit in the HMI

- Continuous monitoring and automatic registration of all limit value violations during machining

- Export function of all registered events in tabular form

- High transparency and sensitivity with regard to tool balancing due to simple operation

- Improved dimensional accuracy, surface quality and reduced tool wear due to the consistent use of balanced tools

- Approach to the workpiece with contact detection by means of motor current evaluation of the grinding spindle*.

- Measuring sensitivity adjustable via user interface

- Individual setting of oversize possible after contact detection

*Available as an extension of the grinding package

- Significant reduction of air cuts, so that the grinding process starts directly at the actual dimension of the workpiece

- Extension of the handling capability, especially when the structure-borne noise on the part cannot be determined clearly

- Full integration in the grinding cycle package

- Technology available for the first time on turn-mill machines, as the perfect complement to gear skiving

- Fully integrated operation on the control including automatic probing of the tooth space

- Full technological support from the DMQP partner for tool support for tool design and for start-up

- Smoothing of the profile line and straightening of the flank lines.

- Improvement of the grading due to smoothed feed marking

- Improvement of concentricity

- Improved overall quality*

*By one quality level, depending on the quality of the previous hobbing process.

- For shop-floor programming with easier integration in the NC-program.

- Easy tool definition in for the NC-program due to the integrated tool library

- Possibility to define the adjusting angle (kappa) for each cutting edge and each operation to achieve the best machining results

* Simultaneous movement of Kappa must be programmed with CAM

- Possible saving of different tools and related tool changing time

- For roughing and finishing, profile turning, external cylindrical and face turning operations with optimized cutting force direction

- Free form surfaces by 5-axis interpolation on the main and counter spindle

- Turning and milling with interpolated B-axis

- Programming the 5-axis movements via customer CAD / CAM systems

- An intellegent Look-ahead function for a continuous process

- Safe decoupling of mold and component at the push of a button (emergency stop).

- Protection of tool and component against damage, in case of an unexpected event.

- Available as an additional option for the technology cycles gearSKIVING 2.0 and Multi threading 2.0

- More safety during start-up of new processes.

- Protection against damage to tool and workpiece, since all coupled axes are safely shut down after emergency stop.

- Switching on and off of the option integrated in the respective cycle.

- Integrated clamping force calculator according to VDI 3306

- Intuitive calculation of the minimum and clamping forces based on the used machining parameters

- Comprehensive package for internal and external clamping with 3 to 8 jaws for turning, milling and drilling

- Avoidance of component deformation due to unknowingly excessive clamping force

- Increased clamping safety

- Faster set-up and safe clamping in combination with iJAW (DMQP RÖHM)

- Production of high precision eccentric cylinders by means of grinding* – Tolerance class IT5

- Simple parametric definition of diameter and eccentricity

- The perfect addition to the machining cycle Excentric turning and milling*.

*Can be ordered as an extension of the grinding package

- As an extension function to the grinding cycle package in order to realize more technology integration (new component geometries)

- Internal or external machining possible

- Selection of different grinding wheels and strategies in the cycle with a plausibility check

- Sensitive clamping force with quick-change jaws

- Controlled clamping force during the machining process

- LIVE measurement of the actual clamping forces

- Optimum clamping force monitoring for process-specific applications

- No component deformation due to unknown clamping force

- Indicator for chuck maintenance, in case of clamping force decrease

- Broaching of internal and external splines with dialogue guided programming

- One-Tooth up to 4-theeth cutting tools with clear tool definition for easy setup.

- Compensation parameters for tool holder deviation in X-direction

- Fast process setup with safer programming

- High flexibility while process adaption and corrections

- Internal and external gears up to module 4*

* on CTX beta TC up to Module 2 I on CTX gamma TC up to Module 4 I depending on workpiece and cutting tool dimensions

- Production of hirth serrations by impact milling on turn-mill machines

- Automatic calculation of the tool path movement

- Position-oriented tooth pairings by determining the angular position of the toothing on the component

- Strong shortening of the process chain because no special machines are needed

- Lower set-up time and comprehensive quality control thanks to the 6-sided complete machining

- More flexibility in technology adjustments due to the flexibility of the Turn Mill machine

- Efficient use of multi-tip turning tools with more than one cutting edge on turn & mill

- Several "sister tools" on one main tool holder

- Reduction of tool change times

- Saves tool magazine space

- By pushing the associated key the X- axis and the Y-axis travel to the positive end-positions for external machining

- Ideally suited to prepare the work space for set-up and alternatively also as an emergency rescue function.

- Easy operation when setting up multi - channel machinery

- Possibilty of a fast response during external machining as a rescue function

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

- Prevention of damage due to tool breakage or tool overload

- Sensorless with automated learning of load limits

- For turning, milling and drilling (up to 3 mm diameter)

- NEW: User interface on CELOS SideScreen

- NEW: Powerful algorithm for efficient monitoring after the first workpiece

- Protection Package: Perfect supplement to MPC Lathes. Price advantage (approx. 40%)

- Save the monitoring limits for each tool and every cutting edge in the program

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

- With interpolation turning, the tool cutter follows a circular movement, where the cutter is always oriented towards the center Of the circle.

- Possible for external and internal machining

- Synchronization and tool path controlled by the cycle

- NEW: in version 2.0 complex turning contours are possible (currently only available on the DMU 50, other machine types will follow)

- Easy manufacturing of sealing surfaces where milling operation might not be possible.

- Complete component processing in one clamping possible

- Reduced investment costs for tools

- Milling of oval and polygonal geometries

- Machining of excentric face polygons possible

- Simple selection of suitable machining strategies

- Simple parametric definition of the shaft-hub connection according to DIN 32711 and DIN 32712

- Enable the machining of small workpieces or those made of long-chipping materials. The perfect complement to Polygon / Oval-Turning.

- Superposition of the turning movement by additional X- and Y-traverses

- Applicable for turning and milling

- Eccentric geometries easy to manufacture

- Exact axis coupling and synchronization in the background

- Easy handling of non-circular parts

- Intuitive user interface for polygons / oval turning

- Making the required geometries with possibilities of simple fine-tuning

- Possiblity of fine tuning of the geometric parameters (long / short Semi-axis and bearing angle)

- Machining can be combined with main spindle or counter spindle

- Programming of the gearing parameters via dialog input

- For spur gear, helical gear and worm gear

- Gear cutters and disk cutters can be used

- Maximized tool life by shifting of the cutter

- Achievable quality ≤ DIN 7

- Gear profile modifications easy to handle

- Use of regrinded tools

- Error prevention by monitoring (e. g. wrong axis cross angle, or wrong turning speed, or turning direction)

- NEW: On-Point Threading - Position oriented thread production

- Free definition of contours, pitches and gears possible

- Creation of large transmission threads, which can not be manufactured by simple thread chasing

- Trapezoidal, buttress and knuckle thread easily programmable at the machine

- Screw conveyor with any profile geometry

- Ball screw nut with cross holes simple to realize

Highlights

- Producing profiles with undercut due to the profile splitting option.

- Applying standard tools and tool holder for left and right sided machining of the flanks

- Surface quality of Ra 0,3 an CrNi-Alloys possible

- Easy to operate through three parameters and without additional sensors

- Avoiding vibrations by means adaptation of the speed

- Application for the main spindle and counter spindle, or for milling machines with FD tables with Direct Drive

- No manual intervention by the operator

- Identical repeatability for all components

- Increased process safety for special applications by avoiding vibrations. example, When using long thin drills or for milling parts with critical clamping

- In combination with the Gildemeister structure programming, A safe and fast reboot of the machining program after an interruption

- Easy program operation especially with multiple spindles or tool magazine

- Displays the process status of the workpiece

- Display of the detailed status on the controller

- Enter remarks automatically by the GILDEMEISTER structure programming.

- Safe re-entry into the program by the press of a button instead of searching for a specific block.

- Structured approach with more than 20 standard programs and more than 200 processing variants incl. automation (bar processing, robot / portal loading, ...)

- Display of the program status with additional markers (EPS) for the sub-programs.

- Hydraulically operated steady rest to support long and slim components

- Expansion of the possibility of using multi-channel machines

- The cycle allows both approaching to and retraction from the steady rest

- Hydraulically operated steady rest in the tool table

- Position-locking the turret leads to increased process safety

- Fix the steady rest position, to position and shape tolerances to comply with the program after reboot

- For straight external and internal gears with shoulder (interference contours)

- Toothing modules between 0.3 – 1.5 with quality 8 according to DIN 3961

- Up to module 2 on CTX gamma TC*

*Quality and machining time depending on tool and workpiece

- High flexibility in the production of gears, where other processes such as gear hobbing or gear skiving are not are not geometrically possible

- Clearly structured input masks for easy adjustment of the process

Turning

- Turning, milling and grinding in one clamping

- Grinding cycles for internal, external and face grinding as well as dressing cyclesn

- Body-borne sound sensors for start-up and dressing

- Full integration of measurement module for relative and absolute LIVE-Measuring – parallel to main time

Milling

- Better surface quality through integration of the grinding technology

- Grinding cycles for internal, external and face grinding as well as dressing cycles

- Body-borne sound sensors for start-up and dressingn

- 1,300 l Cooling system with integrated centrifugal filter for The filtration of particles > 10 μ

- AKZ nozzle unit optionally available for best possible Flushing of the grinding gap

- Expansion of the technological limits of the CTX TC

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality IT5 for ø > 30 mm

- Surface accuracy < 0.4 μ

- Roundness < 5 μ

- Quality 5 for ø < 120 mm

- Quality 4 for ø > 120 mm

- Centring tip mounted on the turret

- Centring tip data is saved directly in the tool memory

- For fixed and spring-loaded centring tips

- Easy operation for positioning the centring tip

- Position-locking the turret leads to increased process safety

- Pressing force of the tip is variable, programmable and monitorable

- Process-oriented adjustment of the feed rate n relation to the table loading

- Minimization of machining time with maximization of the component quality

- NEW: Now also available for CTX TC. Ideal machining result with the highest machine dynamics*

*without consideration of feed weight

Turning

- Measurement and correction of the position of turning and Pivot axes (C4, C3, B)

- Sag compensation possible

- Can be used in combination with standard probes from customers (recommended Renishaw, Blum)

Milling

- Toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machine configuration

- All head variations and table axes

- Reliable re-calibration of the machine before a highly precise processing

- Continuous documentation of machine accuracy

- No rejected parts due to unknown Geometric-deviations

- Periodic recalibration of the machine with comprehensive documentation

- Highest kinematic accuracy in self-regulation

- Automatic optimization of servo drives parameters for Main- and Sub-Spindle

- Reduction of Setup time

- Optimization of machining result

- Setup Time reduction

- Automatic determination of parameters independent from machine operator experience

- saving the setting in NC-program for more quality assurancet

- Higher stability due to optimal force transmission in thelongitudinal direction of the tool holder

- Generation of tool feed in the Y-direction for parting off components at a push of a button

- Compatible with the standard cycle CYCLE92 (Part off cycle), so that the operator can program as usual (ShopTurn and DIN / ISO)

- Up to three times higher productivity possible (3x feed) with simultaneously improved chip control

- Reduced noise level and higher surface quality through more tool stability

- Less material loss due to reduction of the parting width

- Application especially for multi-channel machines for time analysis of the production process and as a basis for the cycle time optimization

- Individual zoom in to view minute details for cycle time optimization

- Histogram up to three channels

- Provides the basis for cycle time optimization by graphical inputs

- Save / Load the recorded data to compare individual optimized steps

- Structured input parameters for the groove geometry, the tool and the machining strategy

- Inner and outer grooves in any position and number freely adjustable

- Easy compensation of tool displacement + Calculation of residual strokes based on selected machining strategy

- High flexibility in the production of any groove geometries with standard tools on standard machines

- Reliable alternative when pushing with driven tools is no longer an economical or technological solution

- Advantages of rigid machine guidance for better groove quality

Service & Training

Comprehensive carefree service and training for your production

Take advantage of our full-service offering and hands-on training to maximize machine performance and minimize downtime. With comprehensive maintenance packages, original spare parts and tailored training programs, we can take your production and your team to the next level.

Downloads & Technical Data

Configurator

Configure your new CTX beta 1250 TC

You would like to configure your machine by your own? And experience the variety of technical solutions online by yourself? The brand-new DMG MORI machine configurator is offering you the perfect basis! Easy, intuitive and lucid you can specify and customize your own CTX beta 1250 TC fitting to your individual needs. At any time, at any place! Start right now!

Special technical articles, analyses and background information on topics that move our industry.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://mydmgmori.com/

Thank you very much for your interest.

Please fill out the form below to download the requested document.

If you accept the storage of cookies, this form appears only once during your visit.